Theta TTS | Progresssive Stamping

This component demonstrates innovative design. What used to be two separate stamped parts staked together is now produced in one die that combines three operations to produce this assembly in one process.

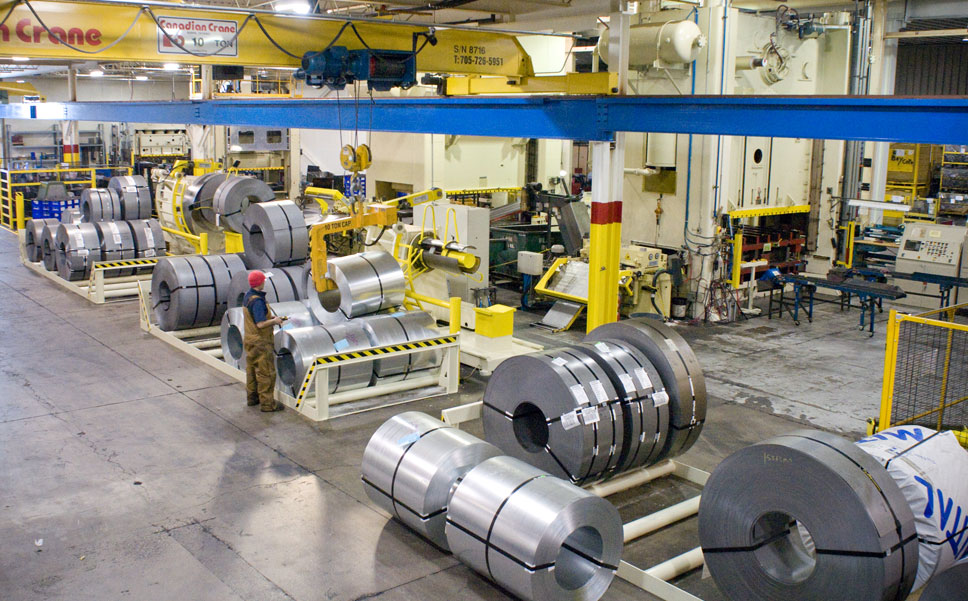

We take progressive stamping to a new level. Our designers re-engineer the manufacturing process by breaking down complex challenges into simple steps. Then our tooling experts implement the process, allowing us to deliver production solutions that would have once seemed impossible. To save you money we incorporate additional in-die processes. We’re experts in making things manufacturable.